- Customized graphene plastic masterbatches can be tailored to the customer’s specified base materials and incorporated directly according to the customer’s processing methods and formulations.

- In engineering plastics applications, the masterbatch enhances mechanical strength, thermal conductivity, and electrical conductivity.

- In textile applications, it increases far-infrared emissivity, providing effective heating and thermal-insulation performance.

Enhanced Heat Dissipation

Increased Mechanical Strength

Increased Electrical Conductivity

Far-infrared Emissivity

Heat-retention Capability

Other Composite Materials

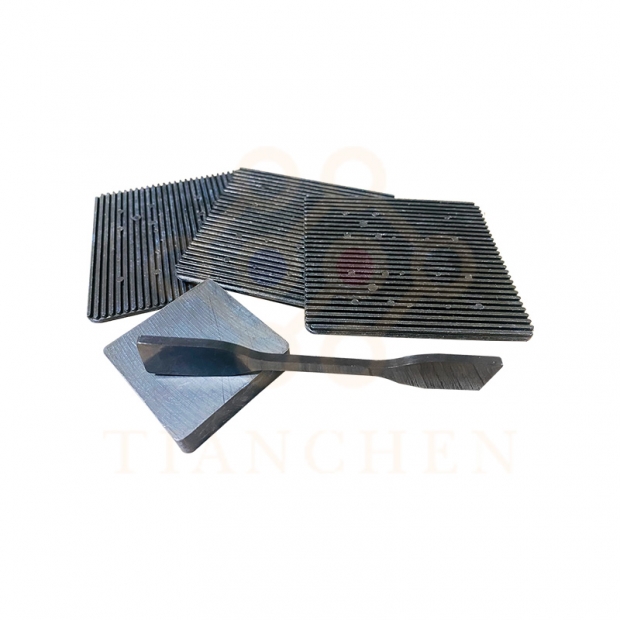

PET & Nylon Dual-Function Masterbatch

Engineering plastics applications: Can enhance properties such as mechanical strength, thermal conductivity, and electrical conductivity.

Textile applications: Can provide far-infrared emissivity to achieve warming and heat-retention effects.

Plastic Composite Material

Leveraging graphene’s exceptional properties, rubber products gain improved thermal conductivity, electrical conductivity, mechanical strength, and wear resistance.

Graphene Down Material

The manufacturing process is environmentally friendly and non-toxic, graphene down utilizes graphene’s far-infrared radiation capability to significantly enhance overall thermal insulation performance.